Dr.

Aleksandr

Novytskyi

Processing of rock

basalt types in

different types of

fiber, a personal

information site

Dr.

Aleksandr

Novytskyi

Processing of rock

basalt types in

different types of

fiber, a personal

information siteBasalt fiber reinforced concrete

Along with the widespread use of reinforced concrete special attention, in our opinion, deserve composite materials, in which the role of the matrix performs the cement stone produced based on Portland cement, as well as valves, various mineral and polymer fibers, and metal mesh and chips. Fibers provide three-dimensional reinforcement of the concrete as compared to traditional valves, which provides a two-dimensional reinforcement.Currently, you can add two directions of creation of composite materials:

- Composites high modulus fibers (steel, asbestos, glass, basalt);

- Composites low modulus fibers (nylon, polyethylene, polypropylene, etc.).

Each composite reinforcing materials have different advantages and disadvantages, but most researchers prefer composites using as a reinforcing material of basalt fibers.

Artificial stone, porous materials (concrete), are characterized by low resistance to tearing and shrinkage cracks during curing. One significant disadvantage of such products is the destruction of the angles produced structures. Avoid the formation of cracks and chips possible in several ways, such as secondary reinforcement wire mesh or rebar, welded wire. But the most effective method of modifying cementitious mixtures basalt, polypropylene and metal fibers. It solves the problems associated with the use of weld fittings in the ceiling, which saves on metal. Thus the polypropylene fiber when replacing a welded wire mesh to prevent the formation of cracks in the structure and increases its bending strength of more than 2%. If a certain percentage of fiber in the mixture, it replaces the secondary reinforcement and provides flexibility, but does not replace structural steel reinforcement. Along with this, the polypropylene fiber has drawbacks: it is deformed at low stress in tension, loses its properties with time and burns when exposed to open flame.

Concrete structure using basalt fibers approaching structure with reinforcement

with steel mesh, but basalt concrete has a higher strength, because its

reinforcing basalt fiber has a higher degree of dispersion in the rock to be

reinforced, the fiber itself has a higher strength than the steel mesh.

Basalt concrete structures can withstand a lot of stress deformation, due to the

fact that the very fiber tensile plastic deformation has not, as of elasticity

than steel.

The relative deformation of cement stone without cracks up to 0.9 - 1.1%.

Such deformation in 45-55 times higher than the limit elongation of reinforced

cement stone.

However, the hardening of the cement stone formed an aggressive environment that

destroys the fiber surface, forming a shell, and the strength of the fiber

decreases slightly to 15%.

But due to the strength of coupling shells stone and fiber increases and thus

increases the strength of the structure itself.

When using the coarse fibers (40 microns), their strength does not substantially

decrease.

Increasing the strength of cement is due to the effect of basalt fiber on

stress concentration in places weakened by structural defects or increased

porosity (in the foam materials).

Fibers made from chemically inert rocks do not react with the salts or dyes and

because binding fiber admixture with additives can be used during the

construction of offshore structures in the manufacture of architectural building

designs with complex surfaces, decorative concrete.

In the production of pavements using basalt fiber asphalt coating protects it

from penetration of anti

anti

ice

salts and aggressive substances, increases surface hardness.

Stay basalt fiber for 6 hours in an environment of concrete hardening, heated to a temperature of 96 C, and then holding for 45 hours at normal temperature does not lead to significant changes in the strength properties of the fiber. Under the same conditions, glass fiber loses its strength 23-35%. The studies found that the addition to the cement matrix of basalt fibers allows:

To increase the compressive strength of the samples at 30 - 40%;

- To increase the strength of the axial tension in three - four times;

- To increase the toughness of the composite in 3 - 4 times.

The strength of composite articles depends on the degree of embedment of the

reinforcing fibers in the cement matrix.

In theory, the strength of the composite increases with increasing content in

the fibers.

However, the reinforcing properties of the concrete matrix with increasing

amounts of fibers are reduced.

When the volume of the fiber tends to 1, the volume of the cement matrix tends

to 0, and the strength of the composite will also be zero.

Therefore, there is a certain ratio of the fiber and the matrix in which the

matrix can provide the maximum degree of embedment of the fibers.

According to some researchers optimum amount of basalt fibers in the composite

should be 20% by weight of cement (9, 10, 12).

The length of the sections of continuous basalt fiber on the one hand determined

by the terms of a uniform distribution of the fibers in the cement matrix (too

long fiber promotes the formation of tangled fibers in the form of "hedgehogs")

and short fibers worsen the degree of reinforcement of the cement matrix.

In this regard, the optimum length of cut taken in the aisles 10-20mm.

The paper (12) on the basis of generalization of domestic and foreign experience directions formulated effective use of basalt fiber as a reinforcing material:

- For the perception of the main tensile and shear stresses instead the core of shear reinforcement;

- To reduce the length of the working valves of the possibility of failure in the continuation of its area decreasing the bending moment due to the increased strength of adhesion with the valve stem to reduce a length of the fiber-reinforced concrete anchoring;

- To reduce the flow distribution valve and a thin-walled concrete elements, in which a large part is assigned to the reinforcement of the design considerations and concrete cover thickness is a significant part of the element.

Also given the application of composite materials based on basalt fiber:

- In the designs, which are increased requirements for stiffness and crack;

- In buildings experiencing the impact of shock and alternating loads;

- In thin-walled design and construction of complex geometric shapes;

- When itinerant reinforcing the most stressed parts of structures;

- In designs, transverse reinforcement which is intended mainly for the perception of installation and transport of loads;

- In the designs, which are increased requirements for frost resistance, water resistance, abrasion and thermal shock resistance.

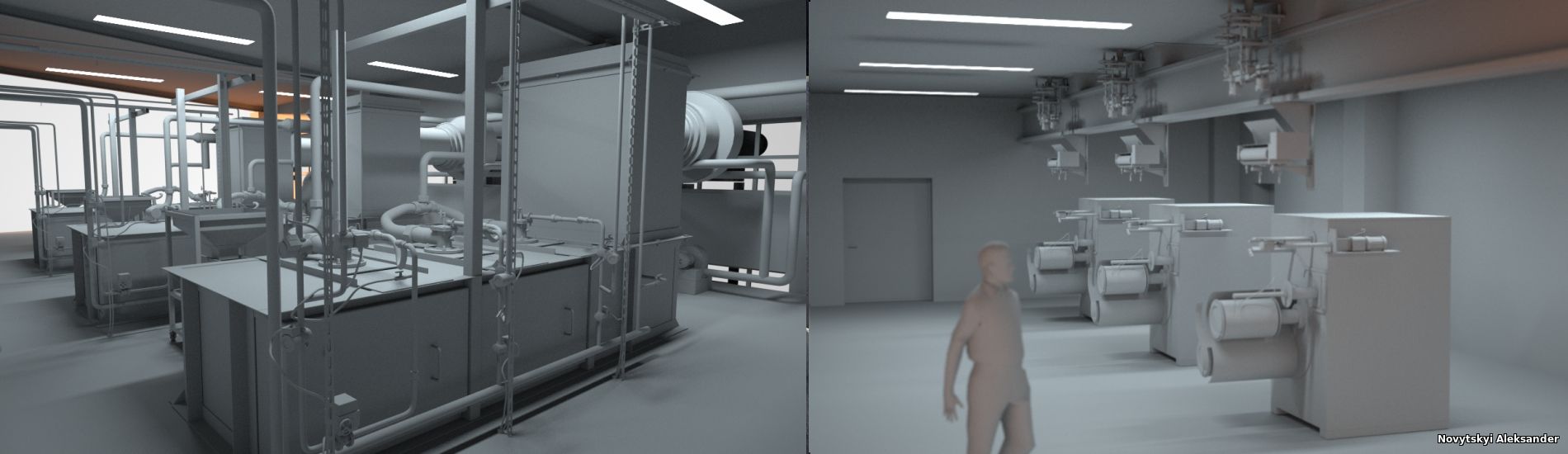

In NIISK Construction Committee of Ukraine, Kiev, developed specific technology

for preparation of concrete, reinforced with basalt fibers (bazaltofibrobeton).

Proposed manufacturing technology with traditional technological schemes and

equipment, special feed lines basalt fiber into the mixer with the required

sealing of the mix on the shaking table without deep vibration.

Scope of the new composite material: flat and thin-walled products, bulk items,

rings, tubes, plates facing channels and silage trenches, road and paving slabs,

elements of permanent formwork, wall panels, building foundations, and others.

At the same time saving the metal fittings on certain types

product is 80 to 100%.

Despite such clear advantages of the composite material, its production did

not come out of the stage of development work, due to the absence of large-scale

production technology sections of continuous basalt fiber as raw material for

the production of concrete products.

This technology developed by JSC "Mineral 7" Yavoriv, Lviv region.

In making the fiber instead of the traditional platinum-rhodium bushing

installation on the applied bushing alloy, which ensures a

low temperature gradient of the area of fiber.

Previously used reels of the "NAS" are replaced with the original design of the

device with a semi-automatic threading.

Which will increase the hourly production of the fiber due to the number of

bushing.

The chemical composition of the rocks processed.

Oxides |

Basalt, Ivanovo-Dolinskoe |

Andesite-basalt, Podgornenskoe deposit |

|

SiO2 |

48,9 |

52,84 |

|

TiO2 |

2,7 |

0,50 |

|

Al2 O3 |

15 |

17,28 |

|

Fe2O3 |

8,8 |

8,97 |

|

FeO |

6,4 |

1,66 |

|

MnO |

0,2 |

- |

|

MgO |

5,1 |

6,30 |

|

CaO |

8,4 |

7,10 |

|

Na2O |

2,3 |

2,20 |

|

K2O |

0,7 |

1,60 |

|

S |

- |

- |

|

P2O5 |

0,3 |

- |

|

H2O |

0,75 |

- |

|

П.п.п. |

2,0 |

1,77 |

|

Сумма |

99,7 |

100,23 |

|

Мк |

4,9 |

5,23 |

|

Мв |

1,97 |

2,6 |

Table 2

Physical and mechanical properties of the fibers

|

deposit |

Diameter, mkm |

Strength limit

Tensile, MPa |

The dynamic modulus of elasticity, kg / mm2 |

|

Basalt, Ivanovo-Dolinskoe |

15,3 |

1700 |

9*1010 |

|

|

30 |

1000 |

7*107 |

|

Andesite-basalt, Podgornenskoe deposit |

17,0 |

1500 |

8,5*1010 |

TABLE 3

Chemical stability of continuous fibers

|

Aggressive environment indicators |

Basalt, Ivanovo-Dolinskoe dр=15,р=15,3 мкм |

Andesite-basalt,

Podgornenskoe

deposit dt cр=17,р=17,0 мкм |

|

Н2О

Resistant, %

|

96,2 |

99,0 |

|

0,5 N NаОH

Resistant, %

|

96,7 |

84,4 |

|

2N NаОН Resistant, % |

81,3 |

77,3 |

|

2N HCI Resistant, % |

76,1 |

82,5 |

The test results

of application segments

of fiber diameter

30-60 microns and a

length of 5 to 15

mm. The fiber content

of 0.2% in the concrete.

1. The distribution

in the concrete mix -

even without the

additional time;

2. Compressive strength

after 10 days

higher than 10%

compared with samples

without the fibers;

3. The bending strength

after 10 days

higher than 80% compared

with samples without

fiber.

Literature

1. Волчек И. З. Использование различных видов волокон в производстве асбестоцементных изделий. Обзорная информация, М. 1986.

2. Патент ЧССР, Кл.32а 37/00/СО3в37/70, №139290, . 15.12.70.

3. Патент Англии, Кл. С1М,/СО4в 15/00, СО3с3/04, №1307357, опубл. 21.02.73.

4. Смирнов Б.И., Зацепин К.С. и др. О стойкости стеклянных волокон в щелочных агрессивных средах. В кн. Специальные материалы для строительства объектов нефтяной и газовой промышленности. М. Стройиздат. 1978.

5. Комлон К. Удобоукладываемость бетонных смесей, армированных волокном. М. Стройиздат , 1088.

6. Патент Англии, Кл. С1М, Д2ВР2Р, (С04в31/06),№100732, опубл. 29.07.70.

7. Пащенко А. А., Сербин В.П., Бондарь В.Р. Стеклоцементные композиционные материалы. Киев, 1979.

8. Петросян С.Т. Технология изготовления строительных изделий с использованием штапельного базальтового волокна. Диссертация на соискание ученой степени кандидата технических наук. Ереван, 1988.

9. Ма9. Махова М. Ф., Гребенюк Н. П. Дисперсное армирование портландцемента базальтовыми волокнами «Цемент», № 2 1980.

10. Крылов Б. Н. Фибробетон и его свойства. Обзор. Вып.4. М. ЦИНИС, 1979.

11. бетон и его применение в строительстве. М. НИИНБ. 1979.

12. Колбаско Э. Б. Прочность, трещенностойкость и деформативность изгибаемых базальтофибробетонных и комбинированно армированных элементов.

Some aspects of the technological process of CBF

Production of continuous basalt fiber based on the melting in the furnace crushed basalt, followed by stretching of the resulting melt filaments. The formation of filaments through holes in the bushing....

Read more

Technology of production continuous basalt fiber

Planet earth has rich deposits of a variety of natural stone materials, the outputs of which the surface is very beautiful and sometimes unique geological monuments of history...

Read more

Concrete reinforced with basalt fibers

At present, it has developed two directions of creation of composite materials: - Composites high modulus fibers (steel, asbestos, glass, basalt); - Composites low modulus fibers (nylon, polyethylene, polypropylene ....

Read more