Dr.

Aleksandr

Novytskyi

Processing of rock

basalt types in

different types of

fiber, a personal

information site

Dr.

Aleksandr

Novytskyi

Processing of rock

basalt types in

different types of

fiber, a personal

information siteTechnological aspects of suitability of rocks deposits of individual countries for the basalt continuous fiber

Due to its unique properties, the materials based on basalt fiber are widely use in various industries, such as:

- Automotive (filters, gaskets, brake pads, exhaust pipes, sound insulation.)

- Petrochemical industry (filters for cleaning of process gas, sound mufflers in industrial installations, filters for waste water treatment from oil products, technological lines);

- Construction industry (non-flammable, chemically resistant and constructions and elements of high-strength);

- Aviation Industry (fireproof insulation board engines, aircraft parts);

- Manufacturing (cushioning pads presses insulation of industrial and domestic refrigerators insulation containers with oxygen, nitrogen, etc.);

- A special technique as a container with increased resource exploitation for the storage and transportation of ammunition;

- The shipbuilding industry (insulation, structural parts);

- In the industrial and civil engineering for the construction of earthquake-resistant buildings;

- Space technology and rocket (wiring insulation, sealing elements, moldings, etc.);

- Food industry (pipes for transporting liquid food products).

Today, the main producers of continuous basalt fiber (CBF) using raw materials deposits in western Ukraine or Georgia. Basically it andesite basalts with an SiO2 content of more than 50%. Melts at temperatures of rock generation have a high viscosity, which determines their use in the manufacture of continuous fiber. Characteristics of basalt fiber produced close to the characteristics of high modulus fiber. However, chemical resistance, strength and heat resistance of these fibers substantially exceed the fiber. All this allows us to characterize the basaltic andesites fields of western Ukraine as a reference raw material for basalt fiber.

However, the extensive development of the production of basalt fiber in places of its direct consumption prevent significant material cost of transporting raw materials from places of its occurrence to the place of processing. Sometimes the raw material is delivered from western Ukraine thousands of kilometers away in Russia, China and others.

However, the basic rocks with an SiO2 content of from 45 to 50% of the globe are widely distributed. Deposits of basalt rocks are available in many parts of the world, and in the field of their occurrence there is a wide network of quarries of rocks. Mined material used for construction, and their suitability for producing basaltic fibers has not been studied.

During the research work, we studied a sample of basalt raw material deposits of individual occurrences of Kyrgyzstan, Tajikistan, Syria and China, and a comparison of the characteristics obtained with the characteristics of raw materials Ukrainian deposits. Table 1 shows the average chemical composition of rock obtained by the studies.

Table 1.

The average chemical composition

(% by weight)

of rocks of various deposits.

|

№ |

Country, rock |

SiO2 |

TiО2 |

А12Оз |

Fе2О3 |

FеО |

MgO |

CaO |

Na2O |

K2O |

|

1 |

Tajikistan, andesite porphyrite |

49,05 |

2,83 |

12,49 |

3,98 |

10,25 |

5,37 |

8,54 |

3,34 |

0,65 |

|

2 |

Uzbekistan, basalt |

48,2 |

0,60 |

11,8 |

4,12 |

6,20 |

9,15 |

13,3 |

1,45 |

2,25 |

|

3 |

Syria tefrito-Basalt |

45,88 |

1,91 |

15,48 |

12,5 |

5 |

9,5 |

4,5 |

47,88 |

|

|

4 |

Georgia, basalt |

49,8 |

2,75 |

15,1 |

8,48 |

6,38 |

5,13 |

7,34 |

1,4 |

0,75 |

|

5 |

China, tholeiitic basalts |

48,03 |

2,85 |

12,59 |

3,88 |

8,15 |

5,47 |

10,5 |

2,32 |

2,68 |

|

6 |

Ukraine, andesite basalt Podgornenskogo deposit |

52,8 |

1,17 |

18,14 |

5,28 |

5,1 |

3,72 |

8,44 |

2,24 |

1,37 |

Important technological parameters of production of basalt fibers are the initial and final melting temperature of the raw material. These values are indirectly characterize the energy consumption for producing the melt.

The initial melting point (tn.pl.) is the temperature at which the primary melt breed and its adhesion to the metal plate surface. The final melting point (tk.pl.) is the temperature at which the complete melt flow breed, the surface spreads melt should be shiny, smooth, without any visible crystalline and gas inclusions.

Studies conducted on samples of rock above fields are shown in Table 2.

table 2

Interval starting and ending melting temperature of the samples.

|

Country, rock |

Temperature, 0С |

|

|

ts.m. |

tf.m. |

|

|

1Tajikistan,

andesite |

1150 |

1380 |

|

2.Uzbekistan, basalt |

1140 |

1340 |

|

3. Syria tefrito-Basalt |

1110 |

1320 |

|

4.Georgia, basalt |

1150 |

1400 |

|

5. China, tholeiitic basalts |

1120 |

1320 |

|

6. Ukraine, andesite basalt Podgornenskogo deposit |

1165 |

1400 |

As the table shows the narrowest interval is characterized by melting basalt from China. Accordingly, the preparation of the melt and to develop energy for melting will be lower. 100 more range from basalt tefrito- Syria, and all the other breeds have approximately the same intervals. All rocks have a final melting point less than 1400 0C, while traditionally used for the production of rock RDH with an SiO2 content of more than 50% have tk.pl. higher.

Another important indicator of the suitability of the species for the production of continuous fibers is a melt viscosity. This indicator has an impact on the entire production process, from the homogenization of the melt spinning and finishing. This figure is largely dependent on the melt temperature and determines the possibility of obtaining fibers.

For the study the viscosity of melts, we used the standard viscometer, calibration is carried out on a sample of the reference glass. Relative error of measurement results at a confidence level of P = 0.94, was 6%. In the measurements, the sample was kept in the test melt temperature range for 0.5 hours. In parallel with the measurements of viscosity and temperature of the established upper chapel melt crystallization (Th.l.k.). This indicator shows the upper limit of crystallization of the melt as it cools and is determined by ╚zakalki╩. The measurement results are listed parameters are given in Table 3.

TABLE 3

The dependence of the viscosity of the samples from the melt temperature and the temperature of the upper chapel crystallization. (Tvpk 0 C)

|

Country, rock |

Viscosity mPa s at T, 0С |

Тhlк, 0С |

||||

|

1450 |

1400 |

1350 |

1300 |

1250 |

||

|

1.

Tajikistan, andesite |

142 |

270 |

470 |

880 |

1780 |

1250 |

|

2. Uzbekistan, basalt |

36 |

62 |

102 |

185 |

360 |

1260 |

|

3. Syria tefrito-Basalt |

26 |

50 |

78 |

135 |

268 |

1230 |

|

4. Georgia, basalt |

110 |

170 |

220 |

720 |

1600 |

1250 |

|

5. China, tholeiitic basalts |

22 |

47 |

68 |

190 |

520 |

1220 |

|

6. Ukraine, andesite basalt Podgornenskogo deposit |

155 |

220 |

490 |

945 |

1800 |

1240 |

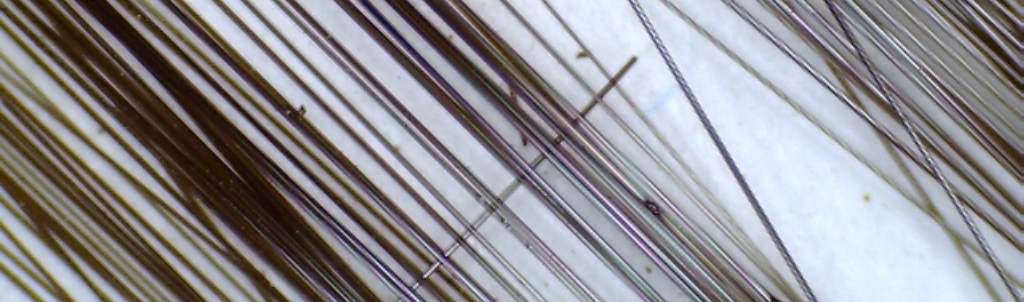

From Table. 2 shows that the andesitic porphyrite forms an alloy with high viscosity and relatively low upper limit of crystallization (Tv.p.k. = 1250 0C). According to criteria previously worked such melts may be suitable (in single-component form) only for the production of continuous basalt fibers and coarse fibers, obtained by a mechanical stretching. Furthermore samples of these melts observed increased amount of crystallites, which makes the fiber drawing from the melt of this species

Fig.

1. The crystallites melt andesitic porphyry Tajikistan.

Most have a low viscosity melt from tefrito- basalt and tholeiitic basalts, on

eligibility criteria are suitable for the production of staple fibers are thin

and rough, there have been some difficulties with the melting of basalt tefrito-,

due to the presence of pores in the rock of the raw material does not

immersed into the melt, which will adversely affect the quality of the fiber and

possibly will contribute to the formation of jams in the discharge device.

The

ability to melt fiberizing studied under laboratory conditions using 14 bushings

with a diameter of 2,2 mm die √.

Continuous fiber drawing speed was maintained constant at 1080 m / min.

One

of the main criteria for assessing the suitability of the rock for a temperature

range of fiber development (Ti.v.).

For forming interval accepted upper and lower temperature limits, within which

the fiber is produced with the same opening without breaking for 30 min.

Determination of the temperature interval of continuous fiber production is to

measure the maximum and minimum temperature making fibers by mechanical pulling

out the thread on a rotating spool.

Formulation fibers is considered to be stable if in the process for their

preparation is not breakage, the pulsing of the melt at the die exit, the

unevenness of the diameter at constant temperature and the level of the melt in

the feeder of the furnace.

The results of investigations to determine the temperature range making fibers

and their diameters are shown in Table. 4.

The temperature range of development and the diameter of continuous fibers.

|

Country, rock |

Тim., 0С |

The diameter of the fiber, micron |

|

1. Tajikistan, andesite porphyrite |

1320-1420 |

9,0-12,0 |

|

2. Uzbekistan, basalt |

1310-1390 |

10,0-14,0 |

|

3. Syria tefrito-Basalt |

1300-1400 |

9,0-12,0 |

|

4. Georgia, basalt |

1360-1450 |

9,0-14,0 |

|

5. China, tholeiitic basalts |

1275-1350 |

8,0-11,0 |

|

6. Ukraine, andesite basalt Podgornenskogo deposit |

1370-1450 |

8,0-13,0 |

Virtually

all breeds foaming

was not observed during the melting

furnace, the melt

surface was clean.

Studies under the

microscope at a magnification showed

that the microstructure of the bulk

glass from China

tholeiitic basalt

field is homogeneous,

without any inclusions

Fig. 2,

Just no

glass inclusions of

basalt tefrito-

Syria.

Fig. 2. Glass of tholeiitic basalt.

In Uzbekistan there are basalt glass mikrokristality no larger than 2 microns, which explains the increased ability of the melt to crystallize Figure 3.

Fig. 3. Glass basalt Uzbekistan.

The microstructure of the bulk glass basalt deposits Georgia homogeneous Fig. 4.

Fig. 4. Microstructure of glass basalt Georgia.

Depending on the operating conditions of fibrous products, the fibers must possess certain physicochemical properties, the most important of which are stable over the length of diameter, tensile strength and chemical resistance to aggressive media.

Elemental continuous fiber diameter was measured under the microscope at a magnification of 750 * Test Tensile determined working length of the sample 15 mm.

The results of measurement of the diameter and tensile strength are shown in Table 5.

Table 5

Physical and mechanical properties of the fibers in a laboratory installation

|

Country, rock |

The diameter of the fiber, micron |

Tensile strength, MPa |

|

1. Tajikistan, andesite porphyrite |

12,0 |

2200 |

|

2. Uzbekistan, basalt |

12,0 |

2000 |

|

3. Syria tefrito-Basalt |

12,0 |

2600 |

|

4. Georgia, basalt |

12,0 |

2000 |

|

5. China, tholeiitic basalts |

12,0 |

1800 |

|

6. Ukraine, andesite basalt Podgornenskogo deposit |

12,0 |

22000 |

Chemical resistant fiber is a standard method three hours boiling in a hostile environment. Indicators of chemical resistance are shown in Table 6.

Table 6.

|

surroundings |

1. /span> Tajikistan, andesite porphyrite |

2. Uzbekistan, basalt |

3. Syria tefrito-Basalt |

4. Georgia, basalt |

5. China, tholeiitic basalts |

6.Ukraine, andesite basalt Podgornenskogo ddeposit |

|

Stability, % |

||||||

|

H/span>2O |

99,4 |

99,1 |

99,2 |

99,0 |

99,4 |

99,5 |

|

2N NaOH |

72 |

76 |

68 |

80 |

85 |

79,2 |

|

2N HCl |

86 |

84 |

76 |

83 |

83 |

58,9 |

Conclusions.

Fibers derived from different rocks have unique properties. Some characteristics of the processes of fiber close. Since the onset of melting temperature difference of not more than 400C. The temperature difference between the end point higher than 800S, this is due to the presence of some breeds more refractory minerals.

Melt viscosity differs significantly, which consequently affects the parameters of fiber production, in particular forming interval. Species have low viscosity fiber forming interval offset to a lower temperature. This is clearly expressed by the example of tholeiitic basalts from China 1275-13500S generation interval.

The diameter of the fiber obtained from various types of approximately the same, but a significant impact on the changes has its hardware design and process parameters. A fiber strength at all virtually identical, except for fiber-based tefrito- basalt from Syria it on average 30% higher. This can be attributed to the large amount of volcanic glass into the rock more than 40%, which affects the availability of a smaller number of crystallite in the glass melt obtained.

The chemical resistance of the fibers is at the same level. It may be noted that the acid resistance of the fibers obtained is more than 17% higher than fibers from andesite Podgornyanskogo field.

Some aspects of the technological process of CBF

Production of continuous basalt fiber based on the melting in the furnace crushed basalt, followed by stretching of the resulting melt filaments. The formation of filaments through holes in the bushing....

Read more

Technology of production continuous basalt fiber

Planet earth has rich deposits of a variety of natural stone materials, the outputs of which the surface is very beautiful and sometimes unique geological monuments of history...

Read more

Concrete reinforced with basalt fibers

At present, it has developed two directions of creation of composite materials: - Composites high modulus fibers (steel, asbestos, glass, basalt); - Composites low modulus fibers (nylon, polyethylene, polypropylene ....

Read more