Dr.

Aleksandr

Novytskyi

Processing of rock

basalt types in

different types of

fiber, a personal

information site

Dr.

Aleksandr

Novytskyi

Processing of rock

basalt types in

different types of

fiber, a personal

information site

Dr.

A. Noyitskyi,

Dr. M. Efremov

National Technical University of

Ukraine "KPI"

JSC "MINERAL7"

(Ukraine)

Research of the mechanism of spreading over the surface of the molten basalt bushing plates of heat-resistant alloys in the manufacture of heat-resistant fiber

Given explain the mechanism of wetting of the materials bushing plates melts rock type basalt. The mechanism swimming bushing plate under the action of the electrochemical transfer. The change in contact angle under the action of electrochemical migration.

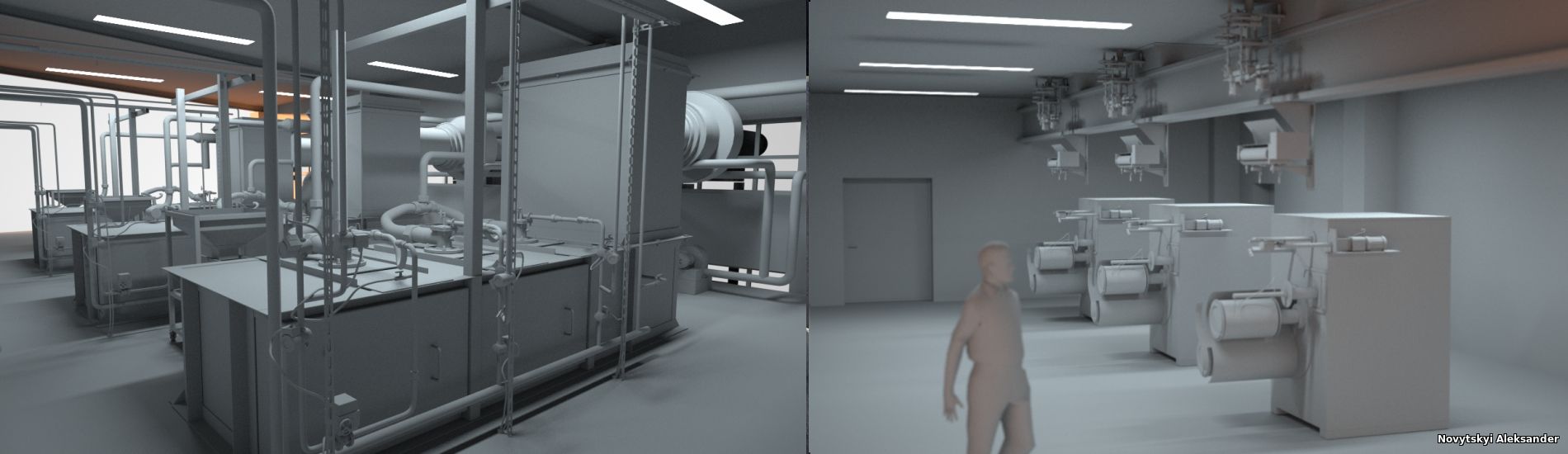

The process of swimming on the surface of the melt plate bushing can be divided into several stages (Fig. 1). Consider the set of factors that determine the course of the individual process steps swimming melt bushing plate.

In the first step, under the action of gravity, the melt passes through the die opening to form the bottom of the spinneret spherical bulb, which is retained on the die cohesive forces and the forces of surface tension. Over time, the bulb increases and when its weight exceeds the cohesive forces, part of the bulb separates from the die and fall down, pulling on a thread. The thus obtained filaments of all the dies are filled in a pulling device which allows continuous filaments hood. Part bulbs remains at the tip of the die and serves as a source for further melt strand formation. In this equation must be met amounts of smelt, which flows into the bulb of the bushing holes and carried away from the bulb in the body of the newly formed filament. However, even in this condition, the melt in the base of the bulb over time spreads along the horizontal generatrix spinneret, passing to the second stage of the process, due to the forces of adhesion between the melt and the metal bushing insert. In the platinum plate, this phenomenon is weak. The plate of heat-resistant alloys spreading process is fairly intensive.

Fig.1. Stages melt flow over the surface of the plate bushing: A die; b - melt; a - "bulb"; g - fiber; Stage 1 - the formation of the bulb, from which the thread is pulled; Stage 2 - on the horizontal spreading of the melt forming die; Stage 3 - leaking melt up the vertical forming die; Stage 4 - the spreading of the melt on the horizontal surface of the wafer; 5 stage - complete swimming plate and stop the spinning.

Melt flow indicator on the metal surface is the contact angle ά (Figure 2), which is associated with the magnitude of the surface tension at the boundary Σ three environments (air - liquid - x, and solid - r) dependence [1]:

Σ т/в - Σ т/ж

Cos ά = --------------,

Σ ж/в

Where: Σ т/в - The value of surface tension at the solid - the air;

Σ т/ж – the magnitude of the surface tension at the interface solid - liquid;

Σ ж/в – the magnitude of the surface tension at the interface liquid - air.

Fig.

2. The contact angle

bushing surface

melt plate.

As seen from the equation,

the main factor that affects the

magnitude of the contact angle

is the value of the surface tension

at the liquid -

air. With the decrease in

the value of Σ

w / in the

wetting of the surface increases.

It is known that surface tension

of the melt and, as a

result, the contact angle

determined by the chemical composition

of the melt and its temperature

(tab. 1,

2).

Table 1

Chemical composition (weight%)

of material.

|

№ |

Rock |

SiO2 |

TiО2 |

А12Оз |

Fе2О3 |

FеО |

MgO |

CaO |

Na2O |

K2O |

|

1 |

Neutral glass |

71,8 |

- |

2,5 |

0,1 |

- |

- |

6,7 |

14,8 |

- |

|

2 |

Basalt Podgornenskogo deposits |

54,1 |

1,02 |

17,23 |

5,7 |

5,03 |

2,6 |

7,99 |

2,18 |

1,56 |

|

3 |

Basalt Ivano - Dolinskogo deposits |

48,8 |

2,75 |

15,0 |

8,47 |

6,39 |

5,13 |

8,34 |

1,.5 |

0,75 |

|

4 |

Basalt Berestovitsa deposits |

49,03 |

2,85 |

12,59 |

3,88 |

10,15 |

5,47 |

9,54 |

2,34 |

0,66 |

table 2

The wetting

angle

of platinum rhodium alloy

melts rocks

|

Rock |

Wetting angle, 0 |

|||||

|

12250С |

12500С |

12750С |

13000С |

13250С |

13500С |

|

|

Neutral glass |

40 |

40 |

40 |

39 |

39 |

39 |

|

Basalt Podgornenskogo deposits |

34 |

28 |

25 |

17 |

12 |

8 |

|

Basalt Ivano - Dolinskogo deposits |

30 |

22 |

20 |

14 |

8 |

0 |

|

Basalt Berestovitsa deposits |

30 |

26 |

19 |

10 |

8 |

6 |

Thus, upon receipt of a continuous glass fiber from the melt using neutral glass bushing plate of refractory metal (complex "Simat", Bulgaria), swimming field plate practically not observed. In the production of continuous fibers from basalt rocks Podgornyanskogo, Berestovetskogo and Ivano - Dolinskogo fields, swimming field plate happened quite extensively.

However, the spreading of the melt on the plate bushing to a large extent depends on the melt adhesion to the metal surface. The higher the adhesion, the lower the values of Σ w / c.

There are several hypotheses about the nature of melt adhesion with metals.

According to the proponents of the mechanical coupling, in contact with the molten metal fills the available surface on the surface micro-cracks and micro cavities, causing a so-called "gear" coupling. Melt flow over the surface contribute to capillary forces and surface tension.

Several authors noted that the metal oxides on the surface contribute to increase its roughness. This has been observed in the case where the metal surface has previously been polished smooth. [1]. A certain importance is the direction of microcracks in the metal. Microcracks, directed perpendicular to the direction of motion of the melt to some extent prevent its spreading.

However, the mechanical coupling is local, distributed on the surface within a few fractions of a millimeter and a great influence on the melt flow over the surface of the metal has not.

To a large extent the adhesion to the surface of the melt and its adhesion to metal depends on the temperature gradient between the melt and the metal.

Δt = t1 – t2 ,

on condition: Δt > 0.

Where t1 и t2 – respectively, the melt temperature and the temperature of the metal.

When approaching the melt temperature and the temperature of the metal increases the likelihood of adherence and further clutch. Adhesion occurs in places where there are local overheating. The production conditions of the melt adhesion occurs already in the case where the temperature of the metal at at least one point exceeds the temperature of the melt. The adhesion strength is largely dependent on the duration of contact and melt the metal and to increase the contact time increases. This oxide layer even monolayer thickness is sufficient to consider them as an absorbent layer, ensuring wetting of the surface of the metal silicate melt, its adhesion and a further clutch.In addition to these factors, the magnitude of the surface tension at the liquid - air (Σ ж / в) and the value of the contact angle is largely determined by the ability of the plate material to oxidation. Not oxidized metal surfaces of silicate melts hardly wetted. An example of this is the process of wetting the surface of the melt platinum plate.

Platinum, being indifferent towards many chemical elements is not inert to oxygen in the atmosphere of O2 and capable of forming a chemical compound PtO2. At normal temperatures, the platinum surface is filled with oxygen and only slightly at 200-4000S amount of absorbed oxygen becomes sufficient for the formation of a mono atomic layer. However, this compound is unstable and at temperatures above 8000S is decomposed in a time commensurate with the lifetime of the activated complex.

In this connection, noteworthy hypothesis melt adhesion to metals through an intermediate oxide layer. Proponents of this hypothesis, suggest that the structure of the metal oxide structure is closer to the melt than to the metal structure. Oxide film for a sufficiently long heating dissolves in the melt and partly in the metal. Thus, the molten metal and connected to each other through an intermediate layer melt saturated with metal oxide.

Given that the bushing to maintain the temperature of the plate corresponding to the temperature generation (1250 -1350 0 C), according to the latest an alternating electric current voltage of 6 volts and power of 30 - 40 amps, it seems appropriate to consider the processes of adhesion of the melt and the metal in the context of electrochemical transformations, taking place in the melt under the influence of an electric current which flows in the plate. Thus the plate itself with respect to the melt alternately performs the anode, the cathode. Under the influence of the electric field on the melt is dissociated anions and cations, to form a short-circuited galvanic dipoles. At high Fe2O3 content of the cathode flow following processes [2]:

![]() Fe 3+

+

e

Fe2+

and

Fe 3+

+

e

Fe2+

and

2Fe2+ + ½ O2 = 2Fe 3+ +O2-,

those. there are intense processes of chemical corrosion. The main cause of corrosion is the presence of ionic melt free oxygen which reacts with the metal to form oxides. In an atmosphere of air, this process reaches a steady state by dissolution in ionic melts new portions of oxygen. Such transformations are possible in the system, if the surrounding atmosphere contains at least small amounts of oxygen. Dross formed on a metal surface, prolonged heating is completely dissolved in the melt. The melt comes into direct contact with the metal surface. The interaction of the melt with the metal ions, iron passes into the melt and dissolved therein. The metal surface is greatly degraded, which promotes lasting "toothed" melt-adhesion to the metal. As studies have shown, the oxide layer even monolayer thickness is sufficient to consider it as an absorbent layer, ensuring wetting of the surface of the metal silicate melts and their grip.If the process of melt flow on the horizontal forming die can be explained by diffusion of the melt and the capillary forces, the vertical wicking melt forming die (Figure 1, Step 3), the influence of these factors can not explain. In this connection, it is advisable to revisit the electrolysis process taking place in the melt under the influence of an electric current flowing through the plate.

In the electrolysis of melts consisting of CaO, Al2O3, Fe2O3, and SiO2 on the electrodes the following processes [3]:

- When the plate serves as an anode,

![]() Si2O52-

2 SiO2 +

½ O2

+ 2e;

Si2O52-

2 SiO2 +

½ O2

+ 2e;

- when the plate serves as the cathode

![]() Fe2O3

+ 2e 2 FeO +O2- ;

Fe2O3

+ 2e 2 FeO +O2- ;

![]() Fe2+

+ 2e Fe;

Fe2+

+ 2e Fe;

![]() SiO2

+2e SiO + O2- ;

SiO2

+2e SiO + O2- ;

![]() SiO

+2e Si

+ O2- ;

SiO

+2e Si

+ O2- ;

As you know, the electrolysis of ion is always accompanied by a fairly intensive mass transfer. In our case, this shift has a pulsating character. With a significant content in molten iron in the transfer process involves short-circuited galvanic dipoles formed ferrosilicon, iron, which under the influence of the electromotive force of a galvanic chain move from the cathode to the anode (Fig. 3a, b.).

Figure 3.

Mechanism swimming

bushing plate

under the action of the

electrochemical transfer.

a -

spreading on a horizontal surface;

b - the vertical

wicking surface.

During halftime

charged ion passes

a certain way, and when

the polarity of the electrode

returns to its original position.

However, under the

influence of the factors set out

above, the melt wets

the wafer surface and

a thin layer adhered

to it, thereby reducing

the contact angle (Figure 4).

Figure 4. Measurement of the contact angle under the action of electrochemical migration. α1- contact angle before switching electric current;

α2- contact angle after the start of the transfer process.

In the next half cycle of a thin layer of melt adhering to build and there is as though "expansion" of the melt on the surface of the plate. Wherein the melt eventually spreads not only over the horizontal surfaces of the plate, and ascends the vertical forming die, filling the entire space between the spinneret. Almost swimming plate occurs within a few hours after the start of operation. In the absence of a melt of iron compounds in the resultant by electrolysis dipole silicon less actively involved in the process of mass transfer and wicking was observed.

Literature.

1. Алексеенко М. П. Когезия и адгезия горячего стекла. Машиностроение М. 1969.

2. Делимарский Ю.К. Электрохимия ионных расплавов. Машиностроение, М. 1978.

3. Делимарский Ю.К. Теоретические основы электролиза ионных расплавов. Изд. Химия, М. 1986.

Some aspects of the technological process of CBF

Production of continuous basalt fiber based on the melting in the furnace crushed basalt, followed by stretching of the resulting melt filaments. The formation of filaments through holes in the bushing....

Read more

Technology of production continuous basalt fiber

Planet earth has rich deposits of a variety of natural stone materials, the outputs of which the surface is very beautiful and sometimes unique geological monuments of history...

Read more

Concrete reinforced with basalt fibers

At present, it has developed two directions of creation of composite materials: - Composites high modulus fibers (steel, asbestos, glass, basalt); - Composites low modulus fibers (nylon, polyethylene, polypropylene ....

Read more