Dr.

Aleksandr

Novytskyi

Processing of rock

basalt types in

different types of

fiber, a personal

information site

Dr.

Aleksandr

Novytskyi

Processing of rock

basalt types in

different types of

fiber, a personal

information siteTechnologies of processing of rocks such as basalt, a fibrous material.

Due

to its unique properties, basalt fiber and products on its basis is becoming

more widely used in all industries.

Materials based on basalt fiber can withstand temperatures up to 7000S,

resistant to acids and alkalis have considerable mechanical strength, thereby

successfully pressed fiberglass products.

Basalt fiber is now available in several versions.

This

is primarily BSTV superthin fiber (basalt superthin fiber), fine fiber BTV (thin

basalt fiber) and continuous basalt fiber BCF (basalt continuous fibers).

Basalt

fiber production is based on obtaining basalt melt in smelters and free from

leakage through special spinneret plate made of platinum or a refractory metal.

Furnaces can be electric, gas or oil burners equipped.

The

raw material for the production of basalt fibers used basalt rocks, the average

chemical composition is as follows (% by weight): SiO2- 47,5-55,0;

TiO2-1,36-2,0;

Al2O3-l4,0-20,0;

Fe2Oz + FeO -5,38-13,5;

MnO-0,25-0,5;

MgO-3,0-8,5; CaO-7 -11.0;

Na2O-2.7-7,5;

K2O - 2.5-7.5; P2O5-no more than 0.5;

SO3- not more than

0.5, no more than 5 p.p.p.-.

- For thermal and acoustic insulation and fire protection systems in residential and industrial buildings and constructions, baths, saunas, cabins and the like. Etc .;

- Insulation for power units, large diameter pipelines;

- Insulation for domestic gas and electric stoves, ovens, etc.

- In three-layer construction sandwich panels;

- For thermal insulation of reconstructed buildings with the installation, both inside and outside;

- For insulating flat roofs;

- Industrial refrigerators and coolers, domestic refrigerators;

- Insulation oxygen Colon;

- Insulation for low temperature equipment in the production and use of nitrogen;

-in industrial cold insulation.

2. Production of thin basalt fiber and products on its basis.

2.1.

Technological scheme of thin fibers.

The

raw material for the production of thin basalt fiber (BTV) is a basalt crumb.

To

obtain 1 kilogram of fiber must be 1.15 kg.

materials. Cost of 1 m. Raw materials is about $ 20.

The feed , in the form of washed basalt crumbs passed through a magnetic

separator is loaded into the melting furnace.

The molten at 1450 - 15,000 with a mass, in the heated feeder is supplied

to the bushing plate, which, under the action of gravity, the molten basalt as

separate streams flowing down to the blowing device.

After blowing basalt fiber enters the fiber deposition chamber and rests

on the receiving conveyor in the form of a carpet.

The unit BTB-500 include the following standard equipment:

1. The melting furnace with heat recovery;

2. The loader;

3. The bushing;

4. The blow head;

5. Camera fiber chamber;

6. The conveyor;

7. Area of service.

8. The cooling tower.

9.

Installation of air purification from basaltic dust.

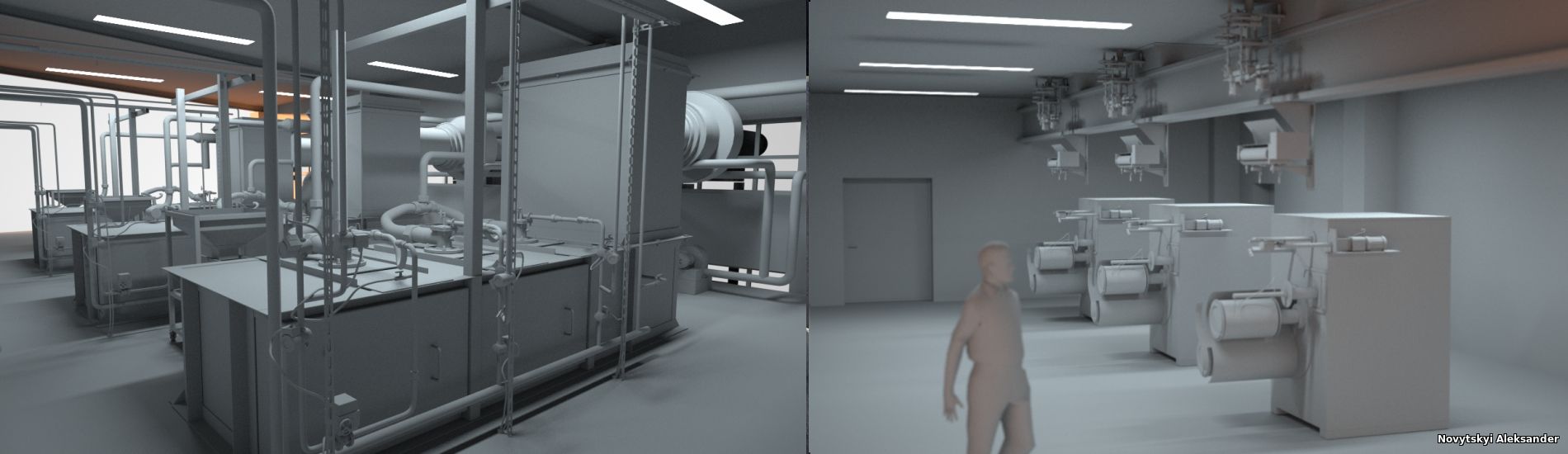

Fig.

1. Schematic diagram of getting

thin

basalt fiber.

Standard equipment includes the installation of the following items:

1. Fan WSC №5 - 2 pcs.

2. Fan dust VNC 6.3 - 1 pc.

3. Transformer TVK-75 - 1 pc.

4. The compressor providing compressed air to a pressure of 0.8 MPa, with a capacity of 12 m3 / min.

The building for the installation of installation BTV - 500 should be fireproof, have an area of 150 - 200 m2 and a height of 15 m. The building can be facilitated modular type, or assembled from reinforced concrete structures. For the operation of the plant, the following energy products:

1. Natural gas F-4-5 kPa Q = 30 m3 / h

2. Compressed air P is 0.8 MPa Q = 12 m3 / min

3. Recycled water R-0.2-0.3 MPa Q = 6 m3 / h.

4. The power supply system, with voltage of 360 V and a capacity of 100-150 kVA.

The power supply system has to be powered by two independent sources, and ensure a continuous supply of electricity to the site.

Also as part of the installation must have:

1. Warehouse feedstock.

2. Warehouse of finished products.

3. Domestic premises.

The

composition of the personnel

Position:

1. Head of

installation - 1 person.

2. The operator - 1 person.

3. Glassoperator

- 1 person.

4. Mode of operation

of the continuous, non-stop.

5. The duration of the work shift

- 6 hours.

6. The number of teams

- 5.

2.3.1. Wired mats.

Wired mats brand MBPA made of thin basalt fiber, which unfolds in the Cutting table and sewed on roving tufting machine. A tufting machine performance up to 20 m3 per shift. Structure of the installation: PANEL table tufting machine. Number of employees in the change of 3 to 4 person.

2.3.2. Obshivnye mats.

Coat MTPB mats and strips PDTS made of thin basalt fiber, which unfolds in the Cutting table coated fiberglass and then sewn to the tufting machine. Performance using a tufting machine 8 - 10 m3 per shift.

Structure of the installation: Cutting tables, sewing machines for stitching fiberglass, tufting machine. Number of employees in the change of 5 - 6 people.

2.3.3. Scrim materials.

Production of canvases from basalt thin fiber can be carried out at the facility BTV-500, in its complete form to a conveyor canvas. Canvas is formed by the natural weave of basalt fibers. The design allows you to install the canvas with a uniform surface density of any length. The thickness of the canvas can also be controlled by a special device mounted on the conveyor.

Number of employees at the facility for 2 people.

3. Production of super-thin basalt fiber and products on its basis.

3.1. TTechnological scheme of superthin fiber.

Super thin basalt fiber and looks like cotton and is a mass of tangled elementary staple fibers up to 3 microns in diameter, held together by natural cohesion. The raw material for the production of super thin basalt fiber (TBF) is a basalt crumb with the size fractions in the range of 3-10 mm. The basalt crumb exception of metallic impurities or foreign bodies in the form of sand, debris, pieces of refractory products, dust.

To obtain 1 kilogram of fiber must be 1.15 kg. materials. Cost of 1 m. Raw materials is about $ 20.

The feedstock , in the form of washed basalt crumbs passed through a magnetic separator is loaded into the melting furnace. Melted at a temperature of 1450 - 1500000 C mass on the heated feeder is fed to a die plate, which, under the action of gravity, the melted basalt as individual filaments pulling flows on device. With pulling thread device fall into the high velocity jet produced by burning gas in the air stream . The filaments are melted and re-swell the fiber. Fibre enters the chamber and drum in form of a web.

With the accumulation of the canvas on the drum, it is periodically removed and applied to the finished product warehouse, or for processing. One installation is equipped with two melting furnaces and two cameras blow. Of the blowing chambers superthin fiber is supplied in common diffuser and is deposited on a receiving conveyor.

Size and weight are shown without filters purify the waste gases.

The plant for the production of BSTV includes:

1. Non-standard equipment:

1.1 The melting furnace - 2 pieces

Loader 1.2 - 2 pieces

1.3 Heat Recovery - 2 pieces

1.4 Burner NB 10.11 - 2 pieces

1.5 Feeder spun - 2 pieces

Pulling mechanism 1.6 - 2 pieces

1.7 Camera blow TG 583222-1 - 2 pieces

1.8 Diffuser - 1 pc

1.9 Intruder forming conveyor

a winding unit - 1 pc

1.10 Service Area - 1 pc.

1.11 Control panel - 1 pc

1.12 The supply

tires

with refrigerators - 4 pieces

1.13 Cleaning System

flue gas - 1 pc

2. Purchased products:

2.1 Transformer TVK-75 - 2 pcs.

2.2 Fan RJC-8 - 1 piece

2.3 Fan VVD№5 - 2 pieces

2.4 Reducer 24-63-40 - 2 pieces

2.5 Reducer 24-80-40 - 1 pc

2.6

electric motors A4 №-1 kw

n = 900 r / min.

- 1 PC

2.7

electric motors A4 №-0,5 kW

n = 1500 / min.

- 2 pcs

2.8 el.magnity MAC 4100 - 2 pieces

2.9 Locking gas-air-water valves

Industrial premises for installation of one unit should have an area of 100

- 150 m m 2 Building height 8 - 10 m. For installation, the following energy

products:

1. Natural gas R-30 - 40 kPa Q = 70 m3 / h

2. Compressed air P 0.1 - 0.15 MPa, Q = 10 m3 / min

3. Recycled water R-0.2-0.3 MPa Q = 15m3 / h.

4. The power supply system, with voltage of 360 V and a capacity of 100-150

kVA.

The power supply system has to be powered by two independent sources, and

ensure a continuous supply of electricity to the site.

Also provided as part of the installation:

1. Warehouse feedstock.

2. Warehouse of finished products.

3. Domestic premises.

4. The production of continuous basalt fiber and

products on its basis.

4.1.

Technological scheme of continuous basalt fiber.

The

raw material for the production of continuous filament basalt is the basalt

crushed rock with a grain size of 5 to 30 mm.

Consumption of raw materials to produce one kilogram of continuous fibers is

about 1 to 15 kg.

Schematic diagram of the production of continuous basalt fiber is shown in

Figure 4. The feed (1) as a scoured basalt crumbs passed through a magnetic

separator (2) is loaded into the melting furnace (3).

The melted at 1450 - 15000 C. mass (4) on the heated feeder (5) is fed into the

jet feeder platinum vessel (6) through spinneret holes which occurs stretch

fibers.

The fibers were then passed through a device for applying lubricant (7) and are

wound on the coil winding apparatus (8).

Finished products are

supplied to the warehouse (9).

Main technical characteristics of the installation for the production of

continuous basalt fiber.

1. Purpose:

manufacture of continuous basalt fiber (diameter 6 - 25 mm.) from basaltic raw

materials.

2. Performance:

the annual 2500,000 kg / year

hour 300 kg / h

3. Raw materials: basalt with a size fraction 3 ... 12 mm

4. Gas consumption: 280 m3 / h

5. Gas pressure 30 - 40 psi.

6. Power consumption: 420 kW

7. Consumption of industrial water 2 m3 / h

8. lubricant consumption 1,5l / h

9.Gabarity (length, width, height): 16m * 18m * 8.5m

10. Support resources.

-contraction air - 12

Nm3 / min. .

- Cooling water (reverse) - 2 m3 / h.

10. The spin vessel 1pc.

Installation structure

1. The melting furnace - 1, the term relining -36 months.

2. Heat recovery - 1pc.

3. loader - dispenser - 1 pc.

4. Transformers TCE - 1 pc.

5. The spin vessel - 1 pc.

6. Control panel - 1 pc.

7. The winding mechanism - 1 pc.

8. Fan

WSC number 5 - 1 pc.

Production

of BCF is to release excess heat.

In winter, the room does not require additional heating system.

Perhaps the use of waste heat for heating nearby buildings and technological

needs.

Industrial premises for installation of one unit should have an area of 300

- 320 m 2 Building height 8 - 10 m. For installation, the following energy

products:

The

power supply system has to be powered by two independent sources, and ensure a

continuous supply of electricity to the site.

Installation

of gas pipelines, water pipelines of the cooling water, air ducts, electric

wiring carried out on the site.

Also as part of the installation must be provided:

1. Warehouse feedstock.

2. Warehouse of finished products.

3. Domestic premises.

4. The

room for the preparation of lubricant.

If not within the enterprise machine shop, the installation part is necessary

to provide mechanical workshops.

Characteristics of the products obtained

1. The fiber diameter of 6-25 microns

2. Application temperature -200 ... + 600

3. Density, kg / m3 2800

4. The elastic modulus kg / mm2 9100 ... 1100

5. Loss in tensile strength (after the heat treatment for one hour),%

20

C 100

200

C-94

400 C 65

6. Weight loss in% after 3 hours of boiling in:

H2O

0.16

2N

NaOH 5.0

2N HCl 2.1

7. Normal sound absorption coefficient of 0.9 ... 0.99

Some aspects of the technological process of CBF

Production of continuous basalt fiber based on the melting in the furnace crushed basalt, followed by stretching of the resulting melt filaments. The formation of filaments through holes in the bushing....

Read more

Technology of production continuous basalt fiber

Planet earth has rich deposits of a variety of natural stone materials, the outputs of which the surface is very beautiful and sometimes unique geological monuments of history...

Read more

Concrete reinforced with basalt fibers

At present, it has developed two directions of creation of composite materials: - Composites high modulus fibers (steel, asbestos, glass, basalt); - Composites low modulus fibers (nylon, polyethylene, polypropylene ....

Read more