Dr.

Aleksandr

Novytskyi

Processing of rock

basalt types in

different types of

fiber, a personal

information site

Dr.

Aleksandr

Novytskyi

Processing of rock

basalt types in

different types of

fiber, a personal

information site

Features production chemical resistance of basalt fiber

Prof. M. Efremov, Dr. А. Novytskyi.

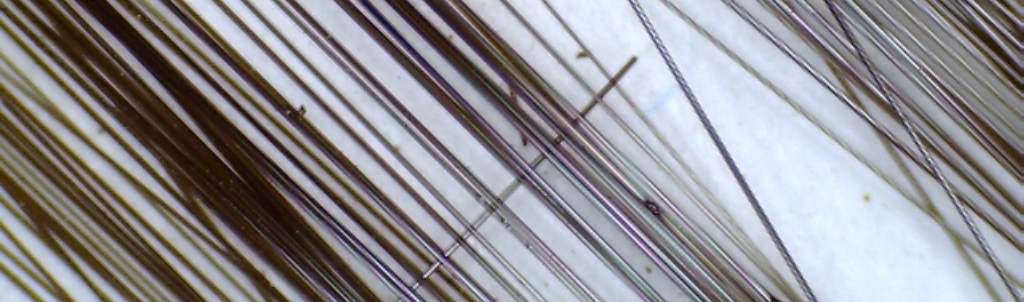

The development of modern technology makes it necessary to create materials that have a low bulk density, good strength characteristics to withstand thermal stress, the influence of aggressive media, as well as filters and high absorbance. One type of these materials have a continuous basalt fiber.

Preparation of the melt takes place in a temperature range from 1050-1070 C - the beginning of an intensive softening and melting at 1400-1500 C. Unlike the glass and slag mix materials, which consist of mixtures of silicate builders, basalt rocks are physico-chemical system, formed by the previous processes upon cooling and crystallization of molten silicate mass - magma.

The process of melting of basalt rock porody- should be regarded as a heterogeneous system, which consists of several physically homogeneous differing among themselves bodies (crystals, glass). They have a complex structure, mainly in the form of mineral compounds - silicates.

Glass of basalt - inorganic solid amorphous body obtained by overcooling of the melt and having a gradual increase in the viscosity of the mechanical properties of crystalline solids. Glass is intermediate between liquid and crystalline substances. Glass does not melt when heated like a crystalline solid and softened successively passing from solid to plastic, and then in the liquid. The absence of structural elements of the long-range order of symmetry and related isotropic brings it to liquids. At temperatures of 700 to 900 C, the crystallization of basaltic glass, which is due to the mineralogical memory. Amorphicity determines isotropy of glass that causes properties of basalt fibers, which have at their connection most of the glassy phase. As the vitreous system produced by supercooled melt, they are metastable phases. The conversion into the glass melt temperature is lowered is accompanied by a gradual increase in viscosity and changes in other physical and chemical properties of the glass, without the appearance of a new phase in the system, which sharply differentiates this process from crystallization. The process of forming continuous fibers occurs at temperatures from 1450 to 1250 C temperature upper limit of crystallization 1260 C. In comparison with the process of crystallization is released characteristic glass transition temperature range in which it exists in a plastic state.

Glass is regarded as a supercooled melt of high viscosity. The main features of the glass structure and characteristics of the process of glass are of practical importance for the process control of production of basalt continuous fiber with desired properties. In the melt near the crystallization temperature and the glass, which is formed from it, some fragments of the crystal lattice are already long enough, but the long-range order in the arrangement of atoms missing. Selecting an independent phase are melt-gas emissions and the removal of the last stage is the content of degassing. This process occurs when exposed to temperatures above the melt 1450 C in melt viscosity of about 150 poise, while, on average two hours. Since the melting point, until the homogenization step are important kinetic effects primarily diffusion rate which determines the completeness of dissolution of crystals in the melt, the separation of gases, the growth of the bubble and eventually, glass homogenization. From other transport phenomena are important increase in the size of gas bubbles and rise in the melt, and the appearance of crystalline phases nucleation and the rate of growth depending on supercooling of the melt. Quartz grains are covered by a network of cracks that develops an isotropic cristobalite and a thin layer of tridymite. Further transformation leads to the development of squamous cristobalite and tridymite thickening layers of the grain. In the presence of alkali cristobalite gradually replaced lath-shaped to form tridymite hastate adhesions. In areas of glass, silica-rich, dendritic stands (characteristic form of crystallization from the melt) cristobalite [1]. The most easily dissolved magnetite ore other minerals, tourmaline, mica, heavier - quartz, and even more difficult - zircon, kyanite (which is quite often the case when a furnace lining leaching of zircon and its adverse effect on the quality of the produced continuous fibers). According D.Tammanu, a tendency to melt overcooling or crystallization is determined by the speed of nucleation and crystal growth linear speed. Both of these values are functions of the degree of supercooling melts and give it according to the highs that do not coincide with each other. Crystallization ability minerals depends on their structure. It is reduced in a number of: spindle, magnetite, olivine, bronze, hypersthene, hedenbergite, augite, alkaline plagioclase, nepheline, leucite, albite, orthoclase, quartz. Depending on the furnace atmosphere and the degree of supercooling melts (degree of nonequilibrium processes) may be implemented and the different directions of crystallization. The fused basalt are three such areas: 1) pyroxene-plagioklazovoe- for the case of equilibrium crystallization, if all goes to the aluminum construction of feldspar; 2) virtually mono-mineral pyroxene - for highly nonequilibrium conditions, pyroxene comprises ferruginous minals and a molecule Cermak; 3) magnetite-pyroxene - with hypothermia during crystallization and in an oxidizing atmosphere, while the iron is bound to magnetite, pyroxene has malozhelezistuyu calcium-magnesium compound [1].

Continuous fiber is produced from a continuous pulling molten glass through the die onto a rotating drum. The process of forming fibers from the melt through a spinneret determined by the viscosity of glass and the nature of its change of temperature, size of the upper bound and its crystallization rate and surface tension. Basalt glass, suitable for continuous fiber must be characterized by a low rate of crystallization, it is most suitable for the formation of fibers at temperatures close to the crystallization temperature of the glass. If the tendency to crystallization of the glass is large, the process must be conducted at a higher temperature than that which corresponds to the desired viscosity, although this leads to additional technical problems. If the glass has a relatively low crystallization rate, then it is possible to form fibers at a certain ratio of viscosity and temperature and in the event that generation temperature corresponds to the temperature of crystallization or below it. The table shows the main characteristics of the rocks of Ukraine [2]. Basaltic glass at temperatures of development should be characterized by a particular viscosity. Viscosity range in which is possible to produce fibers of poise 103,2-103,8. The lower the temperature, which corresponds to this interval, the longer the life spun vessels. Desirably, the upper limit of crystallization as low as possible.

Table

Characteristics of rock deposits in Ukraine.

|

№ |

Deposit |

Тs.m. |

Тf.p. |

Тh.l.k. |

Viscosity at temperature 0С |

Interval fiber production 0С |

||||

|

1450 |

1400 |

1350 |

1300 |

1250 |

|

|||||

|

1 |

Amphibolites Krivoy Rog |

1175 |

1350 |

1230 |

92 |

166 |

270 |

460 |

855 |

1340-1450 |

|

2 |

diabase Saltychiya |

1200 |

1450 |

1250 |

76 |

135 |

246 |

565 |

1150 |

1370-1450 |

|

3 |

amphibolites Stepantsov |

1180 |

1370 |

1250 |

96 |

165 |

300 |

530 |

1050 |

1360-1450 |

|

4 |

Amphibolites Gorishne Plavninskoe |

1170 |

1350 |

1240 |

136 |

204 |

380 |

680 |

1230 |

1350-1450 |

|

5 |

Basaltic andesites Podgornenskoe |

1165 |

1375 |

1240 |

155 |

220 |

490 |

945 |

1800 |

1370-1450 |

|

6 |

Basaltic andesites Seltsevskoe |

1165 |

1400 |

1230 |

150 |

275 |

500 |

1000 |

2000 |

1390-1450 |

|

7 |

Basaltic andesites Shagovskoe |

1150 |

1350 |

1240 |

100 |

170 |

305 |

620 |

1240 |

1360-1450 |

|

8 |

basalts Politskoe |

1170 |

1350 |

1240 |

40 |

62 |

120 |

255 |

500 |

1360-1450 |

|

9 |

basalts Golubitsa |

1165 |

1320 |

1260 |

44 |

72 |

140 |

270 |

495 |

1380-1450 |

|

10 |

Glass |

|

|

1150 |

56 |

96 |

150 |

314 |

570 |

|

Basalt

glass should have a relatively wide range of output, i.e. the temperature range

in which the technological properties of the glass, primarily the viscosity

values are defined and can not be drastically altered.

Basalt glass has a wide range of development, does not require a very careful

control of the temperature, and the process of developing more stable, which

improves quality.

It is desirable that the difference between the final and the initial

temperature was about 1000C generation.

Interval formation is mainly determined by the viscosity interval 103,6-107,6

poise, that is, the change in viscosity of the state of flow of molten glass to

harden.

Graphically, it is expressed in the character of a steep curve (top) glass

viscosity.

There is a direct link between an interval of formation and performance of fiber

production.

The more narrow temperature range is the interval, the

faster the process of development.

Basalt

melt jets emanating from nozzles by the action of hydrostatic pressure and

surface tension takes the form of basaltic glass bulbs.

Cohesive force transmitting pulling force from the fiber to the bulb defined by

the viscosity of the glass in the bulb.

Surface tension basaltic glass contribute to a narrowing of the jet and the

transfer of pulling forces on the periphery of the bulb.

Glass with a high viscosity has a high resistance to tensile, which makes it

necessary to increase the pulling force and can lead to fiber breakage.

Because andesites having increased viscosity at

temperatures generate, respectively, have increased fiber breakage.

With increasing temperature, the melt viscosity is lowered and can reach as

low values at which the surface tension forces contribute to the shaping of

glass in the form of droplets instead of pulling it in a continuous fiber.

In the interval between these two extreme states of the glass has a viscosity of

the area within which there is a process of fiber formation.

For different species according to the table, working viscosity different

area.

When low viscosity is easier going numb on the glass plate bushing, which

complicates the filling fiber.

The bottom of the slot viscosity glass flows more freely, and the ratio of the

viscosity and surface tension of the glass melt becomes indefinite, resulting in

a character pulsiruschemu expiration glass.

The exact mechanism of forming the glass fiber at high speeds is difficult for

theoretical analysis, because of the small volume of the molding area is

characterized by high temperature gradient and is characterized by rapid changes

in the viscosity of the glass.

It was established that occur almost continuous fluctuations in temperature of

about 150-210 ° C within a very short time intervals.

The return of heat from the bulbs is carried out both by radiation and by

convection.

Most of the heat loss by radiation occurs in a region located immediately below

the spinneret i.e.

at the base of the bulb, where the molten glass has the highest brightness, and

that as you get closer to the end point of the glass molding area still most of

its heat is transferred by convection.

To ensure sustainable molding process and achieve a uniform fiber diameter is

necessary to achieve the same speed and the same expiration viscosity glass at

all spinnerets a glass vessel.

The temperature of the bushing is slightly higher field around the longitudinal

axis of the vessel.

Intensification of heat transfer from the surface of the bulb reduces the

average temperature of the glass in the area of molding and working viscosity

range shift towards smaller its value, which reduces breakage and improves the

uniformity of the fibers on their diameter.

Thus for the production of high quality basalt continuous fibers should be chosen not only high-quality raw materials, but also have good control of operating modes. Although dependent on the raw material properties of the resulting fiber core and the fiber scope respectively. In the laboratory of "NII SV" were studies of the chemical and temperature resistance fibers from rocks, as a result of the histogram drawn: fiber resistance to acid (2N HCl), (Fig. 1 a); Resistance to alkali (2N NaOH), (Fig. 1 b); temperature resistance (Figure 1).

According to studies, it is possible to conclude that this is the most heat-resistant fibers from basaltic andesites, basalts least. Canvas from chopped continuous andesite basalt fiber may be used not only at high temperatures but also in an acidic medium, low resistance to alkalis. Amphibolites have different chemical properties, resistance to alkali, but poor resistance to acids. Basalt has a good chemical resistance, low temperature resistance but most. Thus it is possible to determine the application of different fiber raw materials. Using different raw material can be obtained fiber obviously necessary properties.

LITERATURE

- Миронов Н.Л., Портнягин М.В., Плечов П.Ю., Хубуная С.А. Экспериментальная и техническая петрология // Петрология 2001. №1. С.96-99.

- Минерально-сырьевая база горных пород Украины для производства волокон./ Под. общ ред. к.т.н. М.Ф. Маховой. ВНИИТИЭПСМ аналитический обзор. Серия 6.Выпуск 2.1992.С.79-80с.

Some aspects of the technological process of CBF

Production of continuous basalt fiber based on the melting in the furnace crushed basalt, followed by stretching of the resulting melt filaments. The formation of filaments through holes in the bushing....

Read more

Technology of production continuous basalt fiber

Planet earth has rich deposits of a variety of natural stone materials, the outputs of which the surface is very beautiful and sometimes unique geological monuments of history...

Read more

Concrete reinforced with basalt fibers

At present, it has developed two directions of creation of composite materials: - Composites high modulus fibers (steel, asbestos, glass, basalt); - Composites low modulus fibers (nylon, polyethylene, polypropylene ....

Read more