Dr.

Aleksandr

Novytskyi

Processing of rock

basalt types in

different types of

fiber, a personal

information site

Dr.

Aleksandr

Novytskyi

Processing of rock

basalt types in

different types of

fiber, a personal

information siteDr. Alexander. Novyskyi, Dr. Mikhail Efremov

© Mineral 7 JSC (Ukraine)

Presented and analyzed the results of a research of some physical and mechanical properties of basalt fibers and products based on them. Characteristics of the advantages and disadvantages of basalt fibers used for reinforcement of concrete. The expediency of coarse basalt fibers for reinforcing concrete structures.

At present, most of the construction work carried out with the use of concrete. Despite a number of undeniable advantages and wide application, non-reinforced concrete have a low impact strength, low tensile-strength and shrinkage cracks during solidification. All this leads to a relatively low durability of products such concretes. Traditionally, these problems are solved by a secondary reinforcement, which is carried out using structural concrete steel reinforcement, and in the ceiling - the metal mesh. Furthermore, in recent attempts to use particulate reinforcing a concrete matrix using polypropylene, glass, basalt and metal fibers. These methods allows to make the construction of complex configuration, solves the problem of frost products, reduces the overall weight of structures, at a certain dosing fiber replaces the secondary reinforcement and provides the plasticity of concrete, reduce the amount of use of structural steel reinforcement. The dispersion reinforcement of the concrete mass increases the ductility and reduces the formation of shrinkage cracks and unlike steel mesh, which has a value only after the concrete has cracked, fiber prevents the occurrence of cracks in the concrete at the stage when it is in a plastic state [1].

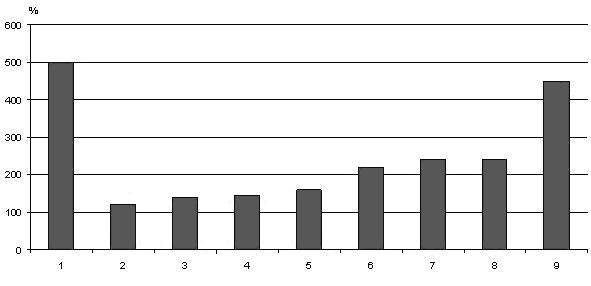

However, during long-term studies in the laboratory, and industrial conditions, it was found that the products reinforced with polypropylene fibers, are characterized by considerable deformation, even at low tensile stresses, due to poor adhesion of polypropylene in the cement matrix. In addition, such products over time lose its strength properties, have a high friability and flammability of the surface when exposed to open flame fiber. The main disadvantages of metal fibers is cathode effect and instability to the corrosive environment of cement slurries. These deficiencies are deprived of concrete products, reinforced with basalt fibers.Studies conducted in cooperation with the Research Institute of Building Materials (Kiev) and the Kiev National Transport University, found that the concrete products, reinforced with basalt fiber, characterized by high durability, a large compressive strength, frost et al. (Chart 1) Studies were performed using basalt fibers in TU V.2.7-26.8-32673353-001: 2007, produced at the Company "Mineral 7", the next part of the control samples of concrete: - Communication - Portland cement 400; - The ratio of water - cement - 0.4; - The ratio of cement, sand, stone - 1: 3: 5. The number of fiber-reinforced concrete is from 1% to 4% by weight.

Figure 1.

Characteristics of concrete

products,

reinforced with basalt

fiber of

comparison with control samples.

Legend:

1 Durability;

2 Compressive

strength;

3 Water

resistance;

4 Resistance

to cracking;

5 Frost;

6 Fracture

toughness;

7 Tensile

strength in bending;

8 Resistance

to abrasion;

9 Impact

strength.

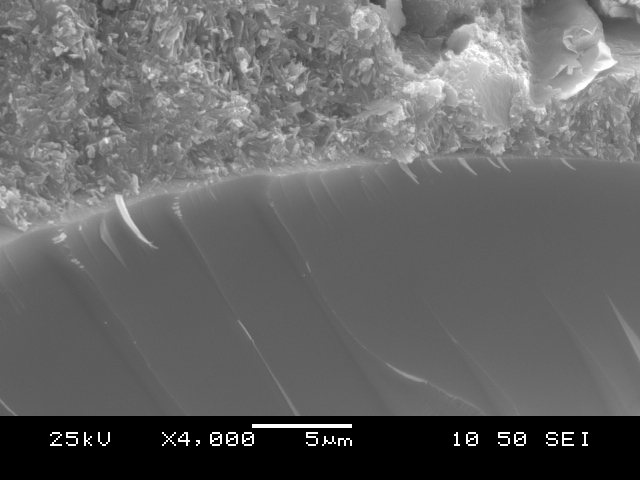

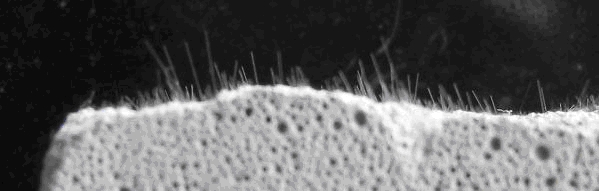

All this is due to the fact that the structure of concrete reinforced with basalt fiber of (CRBF), close to the structure, with the ferrocement reinforcement steel mesh. However CRBF has higher strength and resistant to deformation because reinforcing its fiber provides a higher degree of dispersion of the reinforcement of concrete blocks and he basaltic material is higher than that of steel mesh, strength. Furthermore, CRBF can tolerate large elastic deformations, because the basalt fiber is not subjected to a tensile plastic strain, and under the elasticity than steel. A distinctive feature of the basalt fiber produced at the plant "Mineral 7," is its high adhesion to the cement matrix. Studies carried out by the scanning electron microscope «JEOL» JSM-6460 LV at 4000 magnification [2] have shown that the region of contact between a fiber and the matrix is characterized by tight contact between the surfaces and the absence of cracks and gaps. (Fig. 2)

Fig. 2.

The interface

between the fiber and the

matrix.

As the fiber

material is known

under the action of

aggressive

environment reacts with

the cement

produce tumors

[3].

There is a

partial destruction of the

fiber, the value

of which depends on the time.

The average

failure occurs

to a depth of

4 mm.

Neoplasms reinforce

the connection

to the fiber

cement

matrix. This is clearly seen

in the destruction of

the samples

on the fracture (Figure 3)

that the

weight of cement

and fibers

are destroyed as a

body without

pulling fibers from the

concrete matrix.

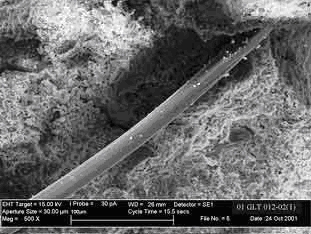

When using the fiber diameter of 30 m under the influence of aggressive environment hardening cement is at least 22 micron fiber diameter of working that has almost no effect on its strength characteristics. The use of fiber diameter of 12 mm, made of basalt roving without lubricant showed that over time it loses all strength characteristics, and sometimes completely destroyed, as the fiber after reaction with the aggressive environment of the concrete decrease in diameter and 4 mm. When using the fiber made from basalt roving with a lubricant, adhesion to the cement weight is virtually nonexistent. WWhen fracture (Fig. 4) are clearly visible torn fibers, pulled out of the concrete matrix.

Low adhesion with the cement binder also exhibit propylene and polyamide fibers (Fig. 5).

There have been studies to determine the loss of strength fibers made from continuous basalt fiber without lubricant, when it stays in the liquid phase hardening Portland cement concrete under normal conditions. The results are shown in Table 1.

Table 1

The strength of basalt fibers after exposure to the liquid phase of Portland cement concrete.

|

Treatment time, hour. |

The diameter of the basalt fiber, micron |

|||||

|

12 |

20 |

440 |

||||

|

Tensile strength, GPа |

||||||

|

GPа |

% |

GPа |

% |

GPа |

% |

|

|

0 |

1,05 |

100 |

0,72 |

100 |

0,55 |

100 |

|

3 |

0,84 |

80,0 |

0,70 |

97,2 |

0,55 |

100 |

|

24 |

0,8 |

76,2 |

0,68 |

94,4 |

0,54 |

98,2 |

|

720 |

0,77 |

73,3 |

0,67 |

93 |

0,53 |

996,3 |

According to calculations carried out the Research Institute of building structures (Kyiv), the durability of fibers, made of rough basalt fiber, in an environment of cement stone is at least a hundred years. [5] The test results of samples BABF made of basalt fiber with a diameter of 30 microns Bole., Is shown in Table 2.

table 2

The strength of cement reinforced with basalt fiber of 40 microns in diameter, with a length of 10 mm.

|

Curing condition of samples |

|

Age sample day |

|||

|

3 |

7 |

28 |

990 |

||

|

Tensile strength samples Flexural MPa |

|||||

|

A control sample without fiber |

|

6 |

7 |

12 |

118 |

|

the normally wet |

2 3 4 |

8 9 9 |

10 11 10 |

19 20 24 |

28 27 229 |

Application for reinforcing concrete, basalt fiber made from rough basalt fiber, allows you to:

- To increase the brand strength of concrete up to 30%;

- To reduce delamination of the concrete mix to 40%;

- To reduce the time of initial and final curing at 25%;

- To reduce the mass of concrete products.

We recommend the following scope of concrete reinforced with basalt fiber of:

- Waterworks;

- Structures operating in harsh environments;

- Construction in earthquake-prone regions;

- Road with heavy traffic;

- Bridges;

- Nuclear power stations and the storage of radioactive waste;

- Floors, concrete pipes and others.

Proceeding from the above CRBF suitable for use in all fields of industrial and civil construction.

Some aspects of the technological process of CBF

Production of continuous basalt fiber based on the melting in the furnace crushed basalt, followed by stretching of the resulting melt filaments. The formation of filaments through holes in the bushing....

Read more

Technology of production continuous basalt fiber

Planet earth has rich deposits of a variety of natural stone materials, the outputs of which the surface is very beautiful and sometimes unique geological monuments of history...

Read more

Concrete reinforced with basalt fibers

At present, it has developed two directions of creation of composite materials: - Composites high modulus fibers (steel, asbestos, glass, basalt); - Composites low modulus fibers (nylon, polyethylene, polypropylene ....

Read more